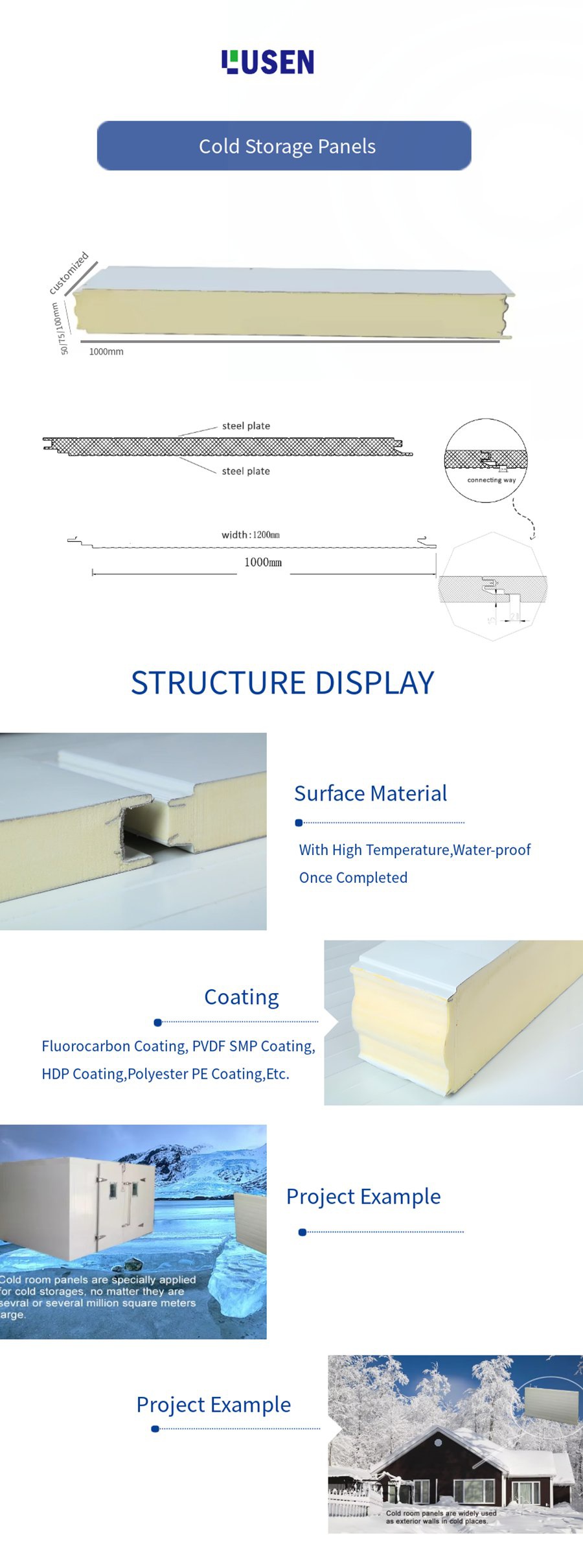

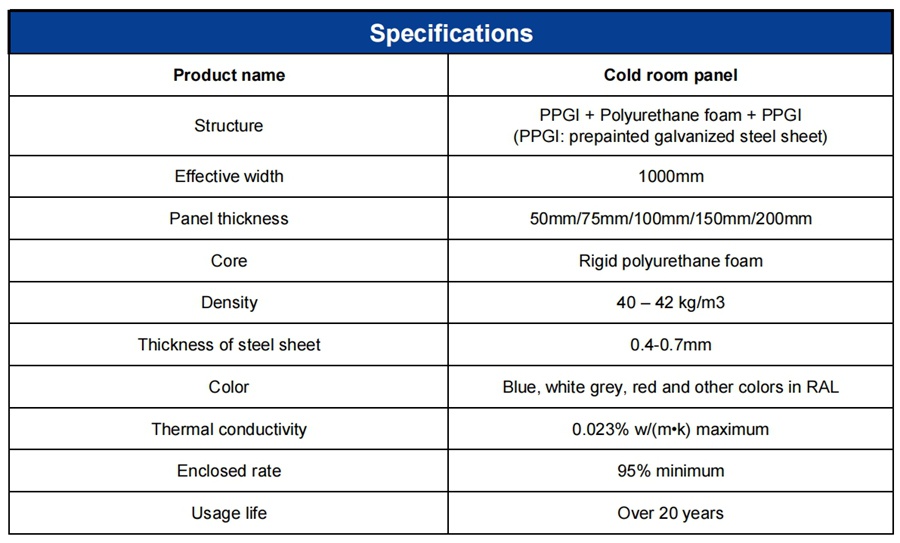

Cold storage panel is a type of insulation products manufactured through automated continuous forming machine technology, offering excellent thermal insulation and energy-saving properties. Cold storage panels consist of lightweight polyurethane foam as the core material, laminated with two layers of color steel plates.

Item No :

Cold Storage Panels 01Order(MOQ) :

1*40HQPayment Term :

30% deposit , 70% before shippingProduct Origin :

CHINAColor :

RAL ColorShipping Port :

Qingdao/Shanghai/ShenzhenLeading Time :

15 working days after deposit50mm/75mm/100mm Environmentally Friendly and Energy Efficient Polyurethane Sandwich Panels for Cold Storage / Cold Room

Features of Cold Storage Panels

High Thermal Insulation:

Low Thermal Conductivity: Made with high-density polyurethane (PU) foam or expanded polystyrene (EPS) foam, which has low thermal conductivity, ensuring minimal heat transfer.

High R-Value: Provides excellent thermal resistance, helping to maintain consistent temperatures and reduce energy consumption.

Fire Resistance:

Fire-Retardant Materials: Often treated with fire-retardant additives to meet safety standards and regulations.

Class A Fire Rating: Many cold storage panels meet Class A fire ratings, indicating high resistance to fire spread.

Moisture Resistance:

Hydrophobic Properties: The core materials are typically hydrophobic, preventing moisture absorption and reducing the risk of condensation.

Sealed Edges: Panels often have sealed edges to prevent moisture ingress, which can compromise insulation performance and structural integrity.

Mechanical Strength:

Durable Construction: Made with strong and rigid facings, such as galvanized steel, aluminum, or fiber-reinforced plastic (FRP), providing excellent mechanical strength.

Impact Resistance: Resistant to physical damage, making them suitable for environments with heavy equipment and frequent movement.

Thermal Bridging Reduction:

Continuous Insulation: The panels are designed to minimize thermal bridging, ensuring a continuous layer of insulation without gaps or weak points.

Seamless Installation:

Interlocking Joints: Panels often feature tongue-and-groove or other interlocking joints, ensuring a tight fit and minimizing air infiltration.

Easy to Install: Lightweight and modular design makes them easy to handle and install, reducing labor costs and construction time.

Chemical Resistance:

Resistant to Corrosion: The facings and core materials are resistant to chemicals, detergents, and cleaning agents commonly used in cold storage environments.

Hygienic Surface: Smooth and non-porous surfaces are easy to clean and sanitize, maintaining hygiene and food safety standards.

Temperature Range:

Wide Operating Range: Designed to perform effectively in a wide range of temperatures, from ambient to extremely low temperatures (e.g., -40°C to -60°C).

Energy Efficiency:

Reduced Energy Consumption: High thermal insulation reduces the load on refrigeration systems, leading to lower energy consumption and operational costs.

Sustainability: Contributes to sustainable building practices by improving energy efficiency and reducing carbon footprint.

Aesthetic Flexibility:

Variety of Finishes: Available in various colors and finishes to match the aesthetic requirements of the facility.

Customizable Sizes: Can be manufactured in different sizes and thicknesses to suit specific project needs.

Regulatory Compliance:

Meets Standards: Designed to comply with international and local building codes and standards for cold storage facilities.

Certifications: Often come with certifications from recognized organizations, ensuring quality and safety.

Applications

Polyurethane cold storage panels are primarily applied in fields or scenarios such as electronics, pharmaceuticals, healthcare, bioengineering, and aerospace.

FAQ

Is it produced according to samples?

It can be produced according to samples or technical drawings based on MOQ

Payment terms:

T/T 30% deposit in advance

Delivery time:

It usually takes only 15-20 days after deposit

(depends on order specific and quantity )

Sample policy:

Free samples are available,shipping fees at clients’expense