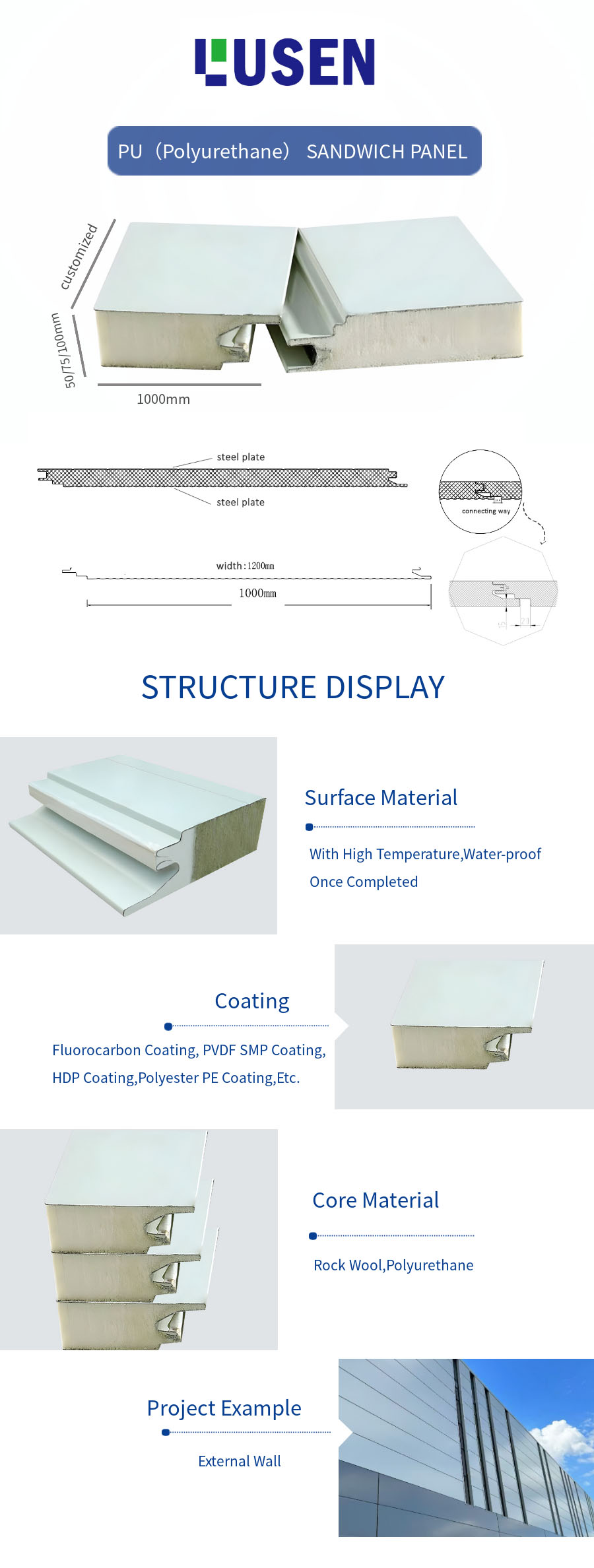

Factory Wholesale Price Most Durable Pre-insulated Sandwich Panels from LUSEN

PU Sandwich Panels, also known as Polyurethane Sandwich Panels, are composite building materials consisting of a rigid polyurethane (PU) foam core sandwiched between two outer layers, typically made of metal (such as galvanized steel or aluminum). These panels are widely used in construction for their excellent insulation properties, structural integrity, and versatility.

Item No :

PU Sandwich Panel 01Order(MOQ) :

1*40HQPayment Term :

30% deposit , 70% before shippingProduct Origin :

CHINAColor :

RAL ColorShipping Port :

Qingdao/Shanghai/ShenZhenLeading Time :

15 working days after depositHigh-Quality Exterior Walls Fire-proof Polyurethane Foam Panels Heat Insulated PU Sandwich Roof Panel Wholesale

Features of Polyurethane Sandwich Panels

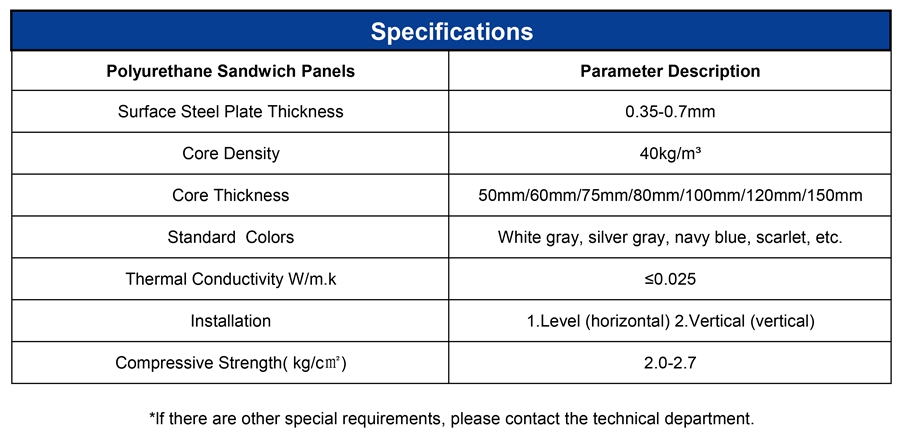

Excellent Insulation:

Polyurethane (PU) foam has a high thermal resistance (R-value), making it an excellent insulator. This helps in reducing energy consumption and maintaining consistent temperatures in buildings.

Lightweight:

PU sandwich panels are relatively lightweight, which makes them easy to handle and install, reducing labor costs and installation time.

High Strength-to-Weight Ratio:

Despite being lightweight, these panels offer high structural strength, making them suitable for various construction applications.

Fire Resistance:

Many polyurethane sandwich panels are designed with fire-retardant properties, enhancing safety in buildings.

Waterproof:

PU foam is inherently waterproof, which prevents moisture absorption and helps in maintaining the integrity of the structure.

Durability:

These panels are highly durable and resistant to aging, UV radiation, and chemical corrosion, ensuring a long service life.

Sound Insulation:

Polyurethane foam has good sound insulation properties, reducing noise transmission and creating a quieter environment.

Versatility:

PU sandwich panels can be used in a variety of applications, including walls, roofs, and floors, in both residential and commercial buildings.

Aesthetic Flexibility:

They can be finished with a variety of surfaces, such as metal, wood, or plastic, allowing for different aesthetic designs.

Environmentally Friendly:

Some polyurethane foams are made with eco-friendly materials and processes, contributing to sustainable building practices.

Easy Maintenance:

These panels are easy to clean and maintain, requiring minimal effort to keep them in good condition.

Cost-Effective:

The combination of high performance and long lifespan makes polyurethane sandwich panels a cost-effective solution for construction projects.

Applications

Walls and Roofs: Commonly used in residential and commercial buildings for walls and roofs.

Cold Storage: Ideal for cold storage facilities due to their excellent thermal insulation.

Clean Rooms: Used in clean rooms where a dust-free and sterile environment is essential.

Industrial Buildings: Suitable for various industrial applications due to their durability and resistance to harsh conditions.

FAQ

Is it produced according to samples?

It can be produced according to samples or technical drawings based on MOQ

Payment terms:

T/T 30% deposit in advance

Delivery time:

It usually takes only 15-20 days after deposit

(depends on order specific and quantity )

Sample policy:

Free samples are available,shipping fees at clients’expense