Sandwich panels are a type of composite material that consists of two outer layers with an inner core. The core is usually made of lightweight materials such as polystyrene, polyurethane, or mineral wool, while the outer layers are often made of metal or other rigid materials. These panels are known for their strength, durability, and insulating properties, making them popular in buildings, particularly for roofs and walls.

Item No :

Sandwich Roof Panel 02Order(MOQ) :

1*40HQPayment Term :

30% deposit , 70% before shippingProduct Origin :

CHINAColor :

RAL ColorShipping Port :

Qingdao/Shanghai/ShenZhenLeading Time :

15 working days after depositLightweight Composite Insulated Sandwich Panels For Modern Steel Buildings

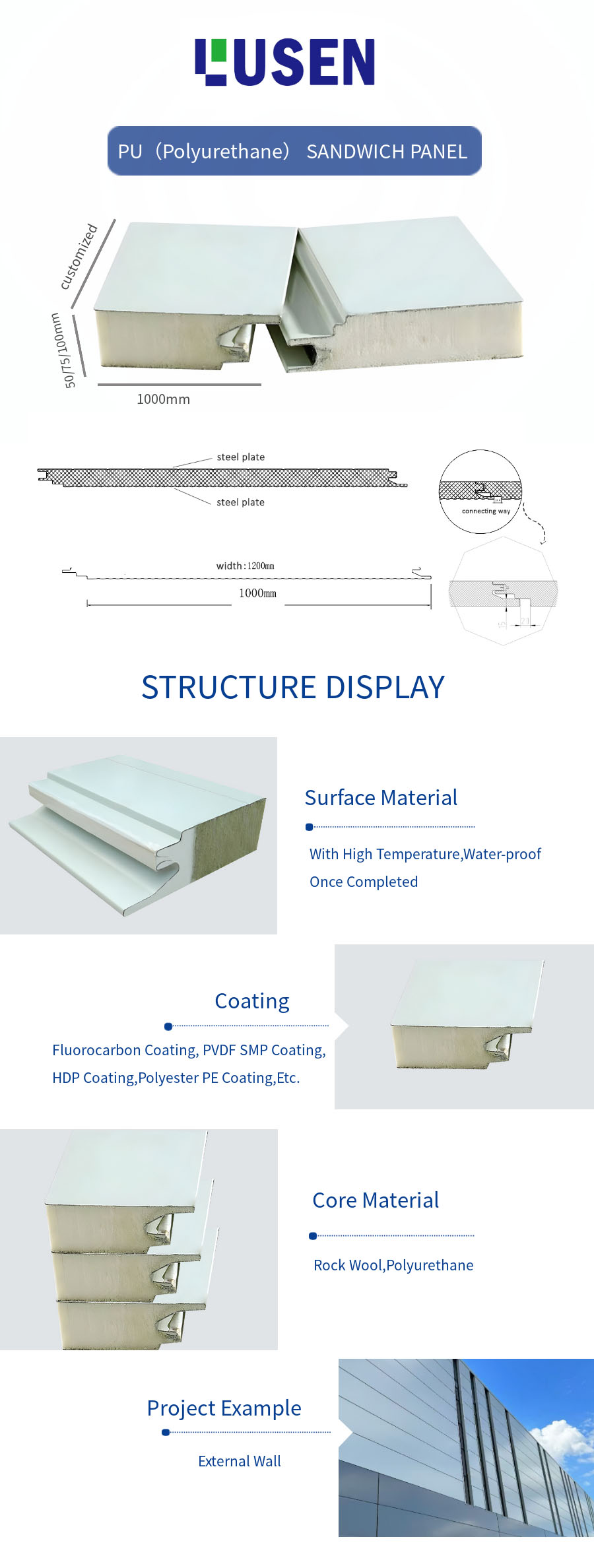

Structural Composition of Sandwich Panels

Face Sheets:

The two outer surfaces of sandwich panels are made from thin yet high-strength materials. Commonly used materials include metals (such as aluminum and steel), composites (like glass fiber and carbon fiber), or polymers. The face sheets are responsible for bearing most of the shear forces and in-plane stresses, while also protecting the internal core material.

Core:

The core is situated between the two face sheets and is typically made from lighter materials such as foam plastics, honeycomb structures (including paper honeycomb, wood, or metal honeycomb). The primary function of the core is to enhance the structural rigidity and stability of the panel while keeping the overall weight minimized.

Features

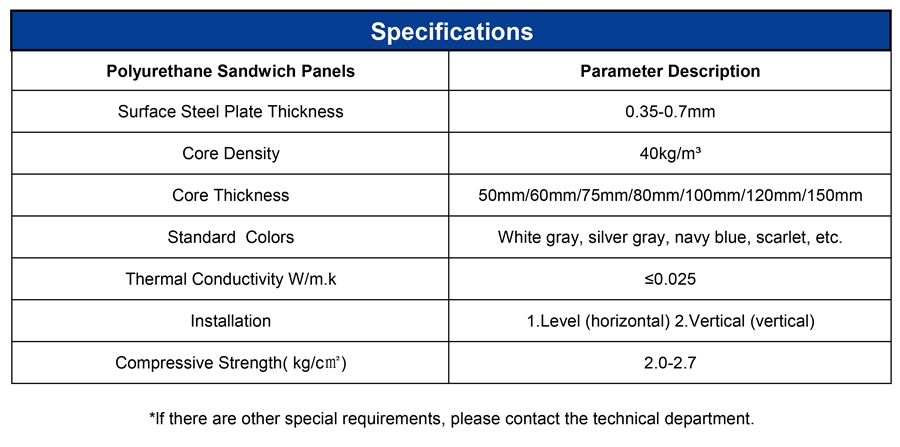

High Rigidity and Strength:

Due to the presence of the core, sandwich panels can provide high rigidity and strength while remaining lightweight, making them suitable for applications requiring both high strength and low weight.

Excellent Thermal and Acoustic Insulation:

The core materials generally offer superior thermal and acoustic insulation properties. Therefore, sandwich panels are commonly used in building exteriors, roofs, and shipbuilding.

Corrosion and Fire Resistance:

Depending on the selected materials, sandwich panels can exhibit excellent corrosion resistance and fire performance. For instance, certain sandwich panel configurations achieve A0 fire rating.

Application Fields

Owing to their unique structural advantages, sandwich panels find extensive applications across multiple industries, including aerospace, automotive manufacturing, construction, and marine engineering.

In the aerospace industry, they are used to manufacture lightweight yet high-strength components such as wings and fuselage sections.

In the construction sector, sandwich panels serve as exterior walls, roofs, and flooring systems, providing outstanding thermal and acoustic insulation.

In the marine industry, they are utilized in shipbuilding for their durability and resistance to harsh environments.

FAQ

Q1:Do you have MOQ?

Payment terms:

T/T 30% deposit in advance, balance payment before shipment or L/C at sight

Delivery time:

It usually takes only 10-15 days after deposit

(depends on order specific and quantity )

Sample policy:

Free samples are available,shipping fees at clients’ expense