LUSEN’s photovoltaic sandwich panels, with their innovative design, convenient installation and disassembly method, high - efficiency photovoltaic power generation performance, and safety and reliability assurance, have become a leader in the photovoltaic sandwich panel manufacturing field.

Item No :

Photovoltaic Sandwich Panels 001Order(MOQ) :

1*40HQPayment Term :

30% deposit , 70% before shippingProduct Origin :

CHINAColor :

RAL ColorShipping Port :

Xiamen/Qingdao/Shanghai/ShenZhenLeading Time :

15 working days after depositSupports Customized Weather Resistance Durability Photovoltaic Sandwich Wall Panels

Meet the unsung heroes of the solar revolution – Photovoltaic Sandwich Panels!

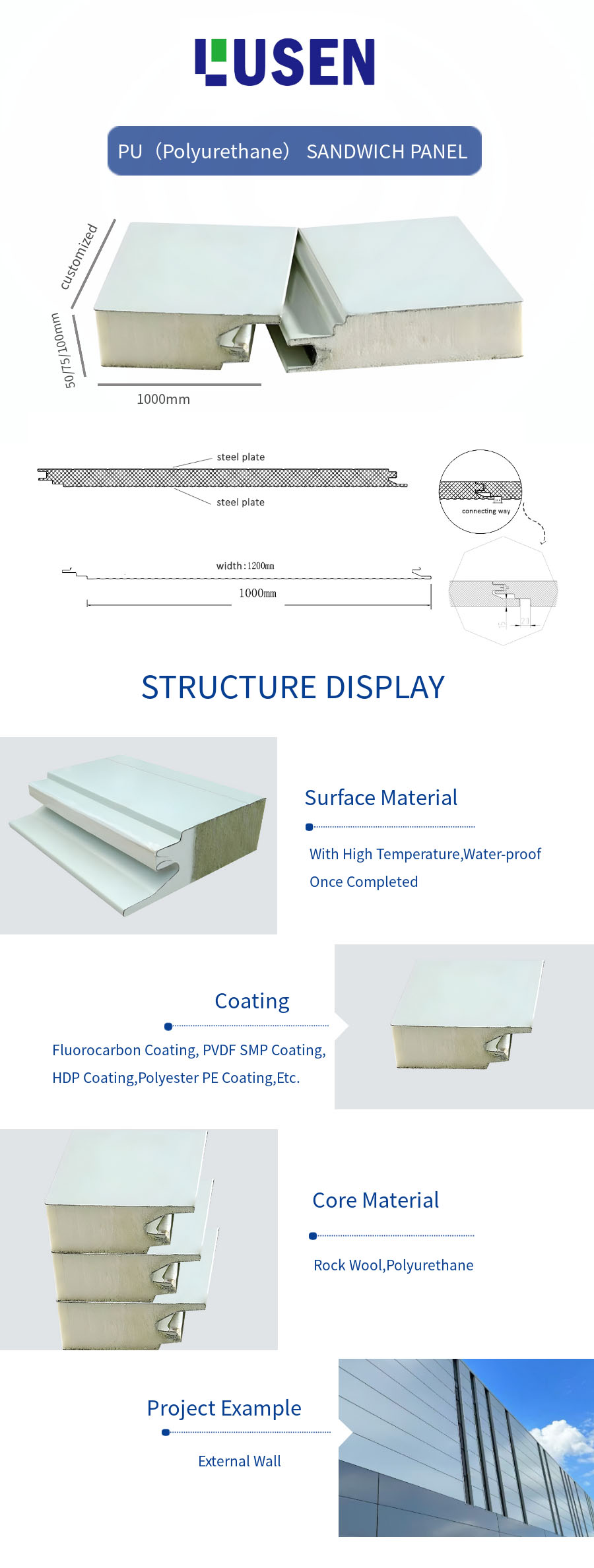

LUSEN’s photovoltaic sandwich panels feature an innovative sandwich structure design that not only enhances product performance but also greatly facilitates installation and maintenance. Specifically, the product consists of several power generation units, each composed of a composite panel and a photovoltaic panel. The composite panel has a first skeleton, a second skeleton, a third skeleton, and a fourth skeleton arranged in a clockwise direction around its periphery. The first and third skeletons are both equipped with several first mating parts and several third mating parts that extend towards and mate with adjacent power generation units. In adjacent power generation units, the first mating part is fitted with a first sealing strip that contacts the third skeleton, and the third mating part is fitted with a third sealing strip that contacts the first skeleton. This design not only ensures structural stability but also effectively prevents the ingress of water and dust, extending the product’s service life.

Durability

The durability of photovoltaic sandwich panels includes the panel’s resistance to aging and weather resistance. High-quality products will not easily fade, deform, or crack during long-term outdoor use. Generally speaking, sandwich panels made with high-quality core materials and outer layers, and treated specially, have better durability.

High - efficiency Photovoltaic Power Generation Performance

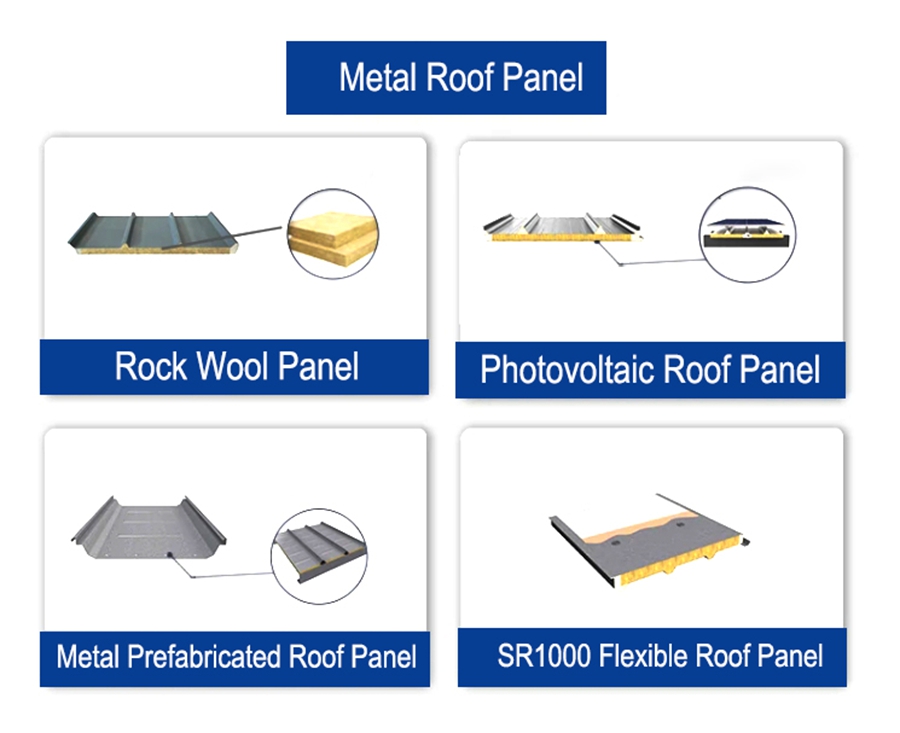

The photovoltaic panels have high conversion efficiency and good weather resistance, maintaining stable power generation performance even under harsh weather conditions.

The Convenience of Installation and Disassembly

The product is designed with a pre - embedded group, one end of which is embedded in the wall, and the other end extends upward vertically to form two top - holding parts arranged at intervals. Adjacent power generation units are respectively equipped with hooks that are hung on different top - holding parts of the same pre - embedded group, realizing the installation or disassembly of power generation units and walls through the hanging method. This hanging method not only simplifies the installation process but also makes maintenance and replacement much easier and quicker.

FAQ

Q1:Do you have MOQ?

Payment terms:

T/T 30% deposit in advance, balance payment before shipment or L/C at sight

Delivery time:

It usually takes only 10-15 days after deposit

(depends on order specific and quantity )

Sample policy:

Free samples are available,shipping fees at clients’ expense