Photovoltaic sandwich panels are composite panels made of two layers of color steel plates with an insulating material (such as polyurethane foam or rock wool) in between, and they have a wide range of applications in the photovoltaic field.

Item No :

Photovoltaic Sandwich Panels 001Order(MOQ) :

1*40HQPayment Term :

30% deposit , 70% before shippingProduct Origin :

CHINAColor :

RAL ColorShipping Port :

Xiamen/Qingdao/Shanghai/ShenZhenLeading Time :

15 working days after depositInstallable Photovoltaic Bracket Waterproof Insulation Color Steel Roof Rock Wool Sandwich Panels

Meet the unsung heroes of the solar revolution – Photovoltaic Sandwich Panels!

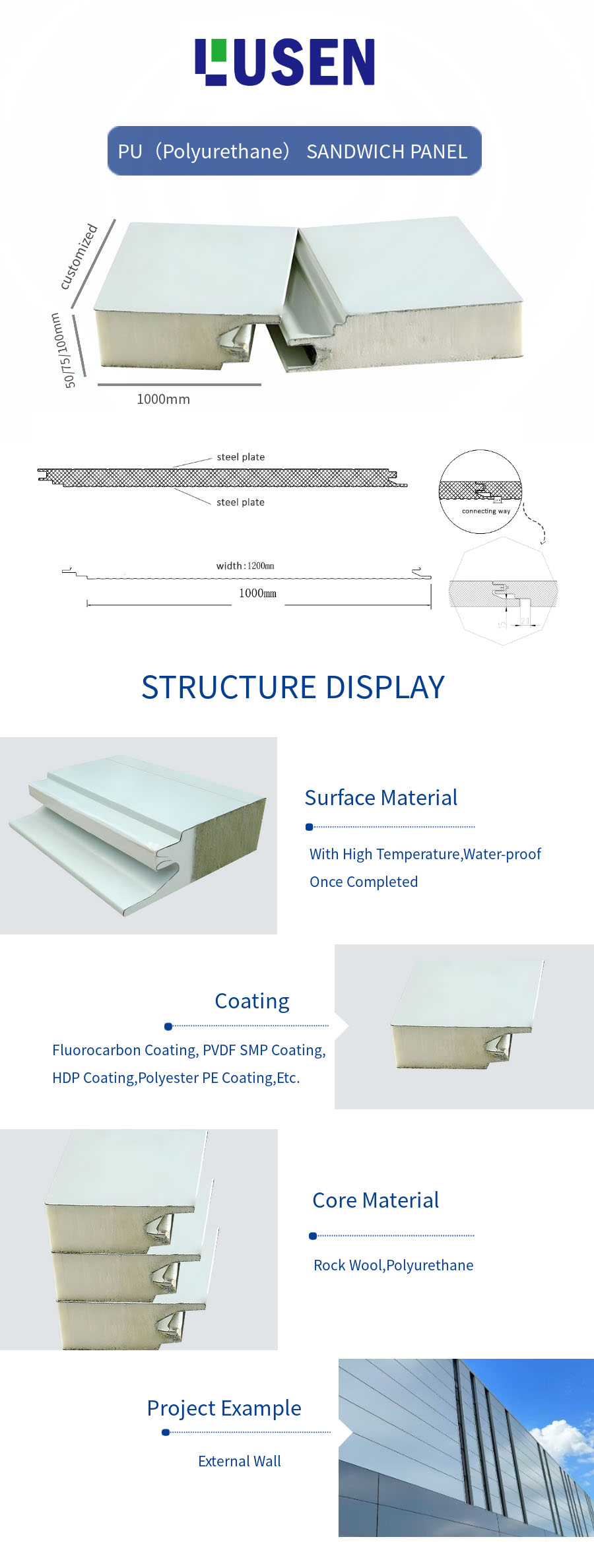

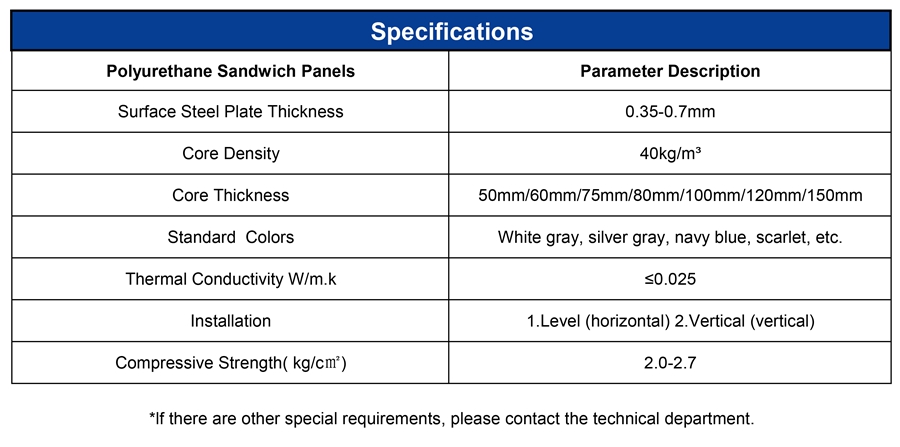

Photovoltaic sandwich panels are composite panels consisting of two layers of color-coated steel sheets with an insulating material, such as polyurethane foam or rock wool, sandwiched in between. They have found extensive application in the photovoltaic (PV) sector.

The characteristics and advantages of photovoltaic sandwich panels include:

Superior Thermal Insulation Performance: The insulating core within the panel effectively minimizes heat transfer between the interior and exterior environments, providing thermal insulation and cooling effects, which significantly enhances the potential for color-coated steel sheets in PV applications.

Excellent Weather Resistance: The surface of the color-coated steel sheets is specially treated to withstand environmental factors like sunlight, wind, and rain, ensuring long-lasting aesthetics and stability critical for the longevity and performance stability of PV modules.

Outstanding Fire Resistance: The insulating materials used in the panels possess high fire-resistance ratings, effectively impeding flame propagation and ensuring the safety of both the building structure and the PV system.

Due to these features and benefits, photovoltaic sandwich panels have a broad range of applications within the PV field, including but not limited to:

Serving as support structures for PV modules, capable of bearing the weight of the solar panels while also resisting external forces such as wind loads, thus ensuring the stability and safety of the PV installation.

Acting as packaging material for PV systems, offering durability through special surface treatments that protect against ultraviolet radiation, safeguarding the PV modules from environmental influences.

Utilized in the mounting systems of PV modules, featuring lightweight properties that reduce the overall system weight, simplify the installation process, and increase construction efficiency.

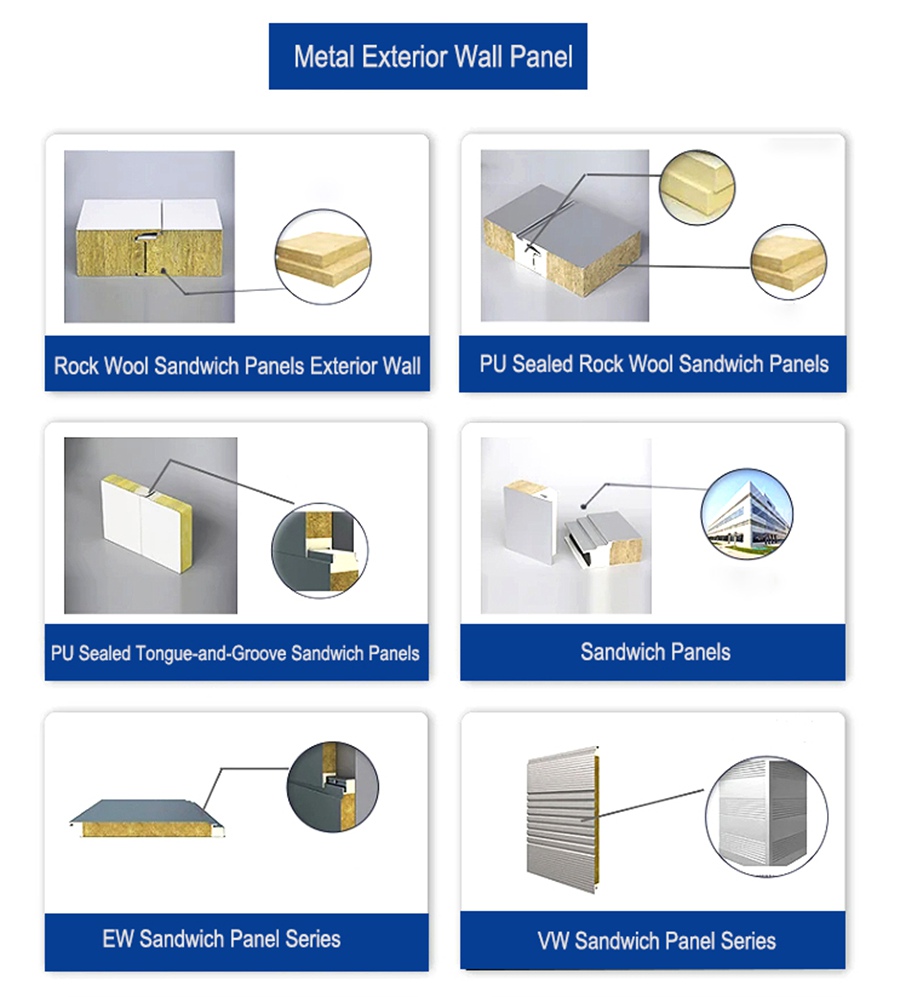

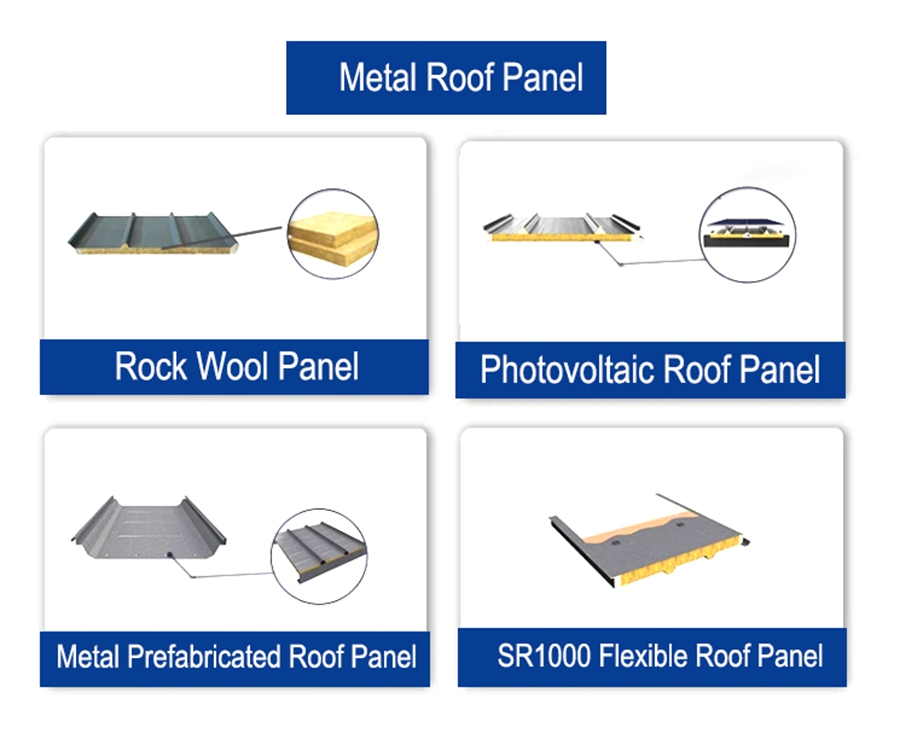

Moreover, there are various types of photovoltaic sandwich panels available to meet diverse PV system requirements, such as polyurethane edge-sealed rock wool sandwich panels, TPO integrated sandwich panels, and standing seam photovoltaic roof sandwich panels.

In summary, as an innovative building material, photovoltaic sandwich panels hold a promising future in the PV industry. With the continuous expansion of the global PV market, the demand for these panels is expected to grow annually.Photovoltaic Sandwich Panels: where the sun meets its match, and buildings get their groove back!

FAQ

Q1:Do you have MOQ?

Payment terms:

T/T 30% deposit in advance, balance payment before shipment or L/C at sight

Delivery time:

It usually takes only 10-15 days after deposit

(depends on order specific and quantity )

Sample policy:

Free samples are available,shipping fees at clients’ expense